It can be frustrating when you apply a polyurethane finish and it doesn’t look right.

You might not know how to fix it or have the time or money to return it to the shop. This blog post will discuss common polyurethane finish problems and show you some simple steps to fix a bad polyurethane job.

We’ll also give you tips on avoiding making these mistakes in the first place.

Let’s get started!

How to Fix a Bad Polyurethane Job

The ultimate way to fix a bad polyurethane job is to sand the surface and reapply the polyurethane coat. Ensure this is done at room temperature and on clean, neatly sanded surfaces. This method works for virtually all problems. However, the best approach is to prevent problems from even arising at all in the polyurethane job by following necessary precautions.

Common Polyurethane Problems and How to Fix Them

Different problems may arise with a polyurethane job, particularly when applying the coat. These problems also arise for several different reasons.

Before any discussion about fixing the problems can commence, it is essential first to identify the problems and their cause.

Below are 15 common polyurethane problems, their cause, tools for fixing them, and how to fix them.

1. Bubbles

Bubbles in a polyurethane job are, as the name implies, bubbles. It is not uncommon to have air bubbles trapped in the coat, which gives an uneven appearance to the coat. The overall result is a disfiguring of the polyurethane job.

Causes

Vigorously shaking the polyurethane can before using: Usually, polyurethane needs to be stirred before using it to ensure uniformity of the fluid. However, many make the mistake of vigorously shaking instead of gently stirring. The result is the entrapment of air bubbles in the finish.

Thick coats: The thicker the coat used, the higher the probability of getting air trapped in the finish.

Rough surfaces: If the surface of the wood is rough, uneven, or unclean before the coat is applied, bubbles may arise. This is due to tiny spaces around the uneven edges on the surface trapping air after applying the finish.

Poor brush selection and use: The type of brush used can play a significant role in forming bubbles. If the wrong brush type is used, the coating process will not be smooth, which can cause bubbles to arise.

Solution

Materials you’ll need:

- Rag

- Mineral oil

- Alcohol

- Sandpaper (220-grit)

How to fix polyurethane finish with bubbles

- Ensure the surface is cleaned before applying the polyurethane coat. Do this by wiping the surface with a cloth dampened with mineral oil (for oil-based polyurethane) and alcohol (for water-based polyurethane). Cleaning with this damp cloth prevents the formation of bubbles.

- Don’t apply thick coats to the wood surface. The thicker the coat, the higher the chances of bubbles arising.

- Remove all bubbles on the finish by tapping with the edge of the brush or your fingertip before drying. This should be done very gently so as not to smear the finish and leave a mark after it dries.

- Reapplication of the polyurethane coat after sanding is the solution to a dried polyurethane finish with bubbles.

Read more here on how to roll polyurethane without bubbles.

2. Puddles or polyurethane too thick

Puddles may also arise in a polyurethane job. The puddles are usually larger than bubbles and characterized by some regions appearing very thick compared to their immediate surroundings.

Causes

The primary cause of puddles is the application of thick layers of polyurethane. When brushing, the regions that first make contact with the brush will be thicker and gradually thin out the further the brush moves.

The result is the appearance of some extra thick regions and some extra thin regions, appearing as puddles. Another reason some regions may appear thicker than their surroundings is when a polyurethane coat is applied on another coat that has not dried out thoroughly.

Solution

Materials you’ll need:

- Rag

- Mineral spirit

- Alcohol

- Sandpaper (220-grit)

How to fix puddles on a polyurethane job

Suppose the polyurethane coat has not dried out when the puddle is observed. In that case, the solution is to dampen a cloth with alcohol (for water-based polyurethane) and mineral spirit (for oil-based polyurethane). For the best results, this should be done quickly.

For instances where the puddle has dried up, the only solution is to sand the surface and reapply the polyurethane coat.

3. Streaking

Streaking happens when a polyurethane finish dries before the streak marks from the brush disappear. This usually happens very soon after brushing. The result is visible steak marks, making some regions darker and more prominent than others.

Causes

Poor brush usage: This is the most typical cause of the streaking problem in polyurethane. Brushing has to be consistent and organized. When the brush is moved excessively over the surface, the chances of having a streaking problem are higher.

Using brushes with coarse bristles: Low-quality brushes with coarse bristles will lead to streak marks when coating. This is common to the overly cheap brushes in hardware stores.

Uneven coat spreading: If you overwork the polyurethane finish on the wood surface in one region and underwork it in another, streak marks may appear on the finished surface. Any form of irregular or disorganized spreading can result in streak marks.

Improperly prepared polyurethane: Streaking is characterized by some regions having more prominent marks than their immediate environments.

One cause of this is improperly prepared polyurethane. Before applying the polyurethane coat, it is advisable to stir the finish to ensure uniformity of consistency. If this is not done properly, streak marks may appear when coating.

Solution

Materials you’ll need:

- Sandpaper (220-grit)

- Quality brushes

Correcting polyurethane finish streaks

Clean the surface with a solvent like mineral spirits or lacquer thinner to remove dust. Try sanding the surface lightly with 220-grit sandpaper to remove any shiny streaks, then reapply the polyurethane.

Sanding the streak marks and reapplying a new coat is a way of fixing the problem if the coat has dried.

When choosing brushes for coating, go for high-quality ones. This doesn’t mean exorbitant but reasonably priced. Cheap brushes are often no good. For oil-based polyurethane, use natural brushes. For water-based polyurethane, use synthetic brushes.

4. Cratering

This is a common problem when applying finishes to wood surfaces. Craters are circular dents that occur on the wood surface. They are usually small in size, appearing as a “fisheye.” Craters may occur in several spots after a polyurethane job.

Causes

The primary cause of cratering is applying the polyurethane finish over contaminated surfaces. Contamination in this context is by dust, silicon, or other chemicals.

Because the paint cannot adhere to these contaminated surfaces, a visible mark is left on the finish after it dries.

Solution

Materials you’ll need:

- Sandpaper (220-grit)

- Rag

How to fix cratering on a polyurethane job

To repair the polyurethane finish, sand the affected areas lightly with 220 grit sandpaper and clean the wood surface with a clean rag. Reapply thin coats of polyurethane while allowing it ample time to dry.

However, care has to be taken to properly clean the wood surface before the reapplication of the polyurethane coat to prevent the same issue from arising again.

Read more: How much polyurethane do I need?

5. Alligatoring – polyurethane cracking

Also known as crazing, crocodile skin, or alligator skin, alligatoring occurs as a network of interconnected cracks in a polyurethane finish.

This causes the texture of the finished wood to resemble alligator skin, hence the name alligatoring. As you would expect, it can be pretty ugly to look at – no offense, alligators!

Causes

Thick coats: If the polyurethane coats applied to the wood is too heavy or thick, cracks may appear. In severe cases, alligatoring can occur.

Cold conditions: If the working conditions during coating are too cold, the surface of the finish may not coalesce well, resulting in crocodile skin. Exposing the surface to intense heat or sunlight will not solve the problem and may even contribute to it.

High moisture: If too much moisture is trapped in the coat, alligatoring may arise when the finish dries. This is caused by applying too much water when preparing the finish.

Poor application of second coats: Second coats are not at all rare when coating. They may be applied on the primary coat or after it has been sanded off. However, if they are applied poorly, crazing may occur.

The poor application includes applying the second coat over a coat that has not fully dried or not removing the initial coat completely before application of the second coat.

Contaminants in the finish: If the polyurethane finish used is contaminated with chemicals or dust, the finish may not coalesce well, causing alligator skins. Also, using expired products can cause a breakdown in the finish, separating some of its constituents, which can cause alligatoring.

Solution

Materials you’ll need:

- Sandpaper (220-grit)

- Rag

The only way to fix a crocodile skin is to sand the surface and reapply the polyurethane finish. The surface has to be cleaned properly before reapplication of the coat.

6. Surface Roughness

Surface roughness in a polyurethane finish is, well, rough surface. It’s that simple. This isn’t about the finish appearing rough but being rough.

Aside from the poor aesthetics, it feels very uncomfortable to touch, defeating the purpose of the finish in the first place.

Causes

Dirty and poorly-sanded surfaces: The most direct cause of a surface roughness problem is if the polyurethane finish is applied over a dirty surface.

This means debris, dust, and other particles on the wood surface can cause surface roughness. This just makes sense, doesn’t it? A similar problem is if the wood is not sanded correctly and is still rough before applying secondary coats.

Contaminated polyurethane: Aside from the wood surface, if the polyurethane finish is contaminated, it can lead to rough finishes. Contamination can be due to other chemicals in the finish, which can occur with low-quality or expired products.

How to fix surface roughness on a polyurethane job

Materials you’ll need:

- Rag

- Sandpaper (220-grit)

If all the polyurethane coats have been applied and the surface is rough, sanding and reapplying the finish is the only solution.

However, if the roughness is noticed before all the coats have been applied, you can still rectify the problem by cleaning the surface thoroughly and sanding properly before applying new coats.

7. Scratches

Scratches are common on furniture and essentially household equipment subject to frequent use. It is one of the few problems on here that you can do little to avoid after an extended period of using the furniture.

The scratches may be superficial, meaning they don’t go deep into the finish or the wood. They are the kind of scratches you’d expect on the case of your phone or your glass screen protector. These scratches may only be visible nearby or on close inspection.

Conversely, the scratches may be deeper into the wood finish. These scratches are almost always noticeable at a glance disfiguring the wood furniture.

Causes

There are tons of reasons the wood surface may get scratched. Using kitchen equipment on the table, placing very rough equipment on the wooden furniture, using sharp tools on the table, and much more are potential reasons for scratches on the wood. The furniture may even get scratched from sanding.

How to fix scratches on a polyurethane job

Materials you’ll need:

- Rag

- Polish

- Sandpaper (320-grit)

- 0000 steel wool

- Mineral spirit

Step 1:Use polish for superficial scratches. These polishes don’t have to be used in large quantities, too. You can decide to spray on the scratch or clean it with a rag.

Step 2: For scratches that result from 220-grit sandpaper, sand the wood with 320-grit sandpaper. Ensure that the sanding here is not vigorous or excessive. After sanding, apply polish to refinish the wood surface.

Step 3: For deeper scratches, you must first clean with a polish using 0000 steel wool. Add mineral spirit to the steel wool to ease the cleaning process. After cleaning with the steel wool, reapply the polyurethane finish on the affected areas.

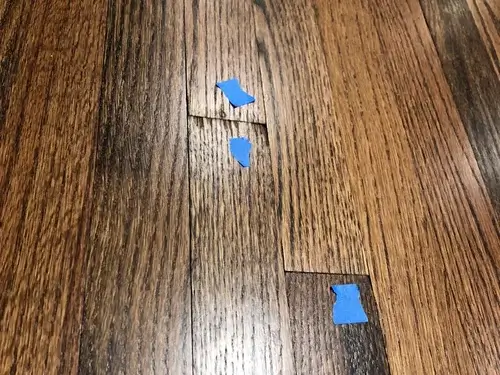

8. Trapped organisms

This sounds unlikely, but it’s true – trust us! Some animals – living or dead – may be trapped under the polyurethane coat. The commonest culprits are very small bugs. This may only become visible after the polyurethane coat has dried.

Aside from animals, other organisms, like fungal spores and insect eggs, may be trapped under the polyurethane coat.

Causes

Trapped organisms are usually caused by negligence when coating. At times, you may not notice the presence of these animals when coating because of their small size.

Some may even see the animals and still apply the coat. The small animal may look inconsequential to the final quality of the finished product, but it can be the difference between a good and bad polyurethane job.

How to fix the problem of the trapped organisms on a polyurethane job

Materials you’ll need:

- Rag

- Sandpaper (400-grit)

Step 1: If the finish has not dried when you notice the trapped organism, you can simply remove the organism with a toothpick.

Be careful not to press the animal down on the finish or try to remove it with your hand. After removing the organism, apply a little finish on the affected surface for best results.

Step 2:For fully dried polyurethane finishes, you will have to sand the affected surface with 400-grit sandpaper and reapply the polyurethane coat.

9. Discoloration/ blotchy polyurethane finish

One of the most annoying issues with a polyurethane job is its discoloration – usually to a yellowish color. What makes this problem particularly annoying is you have little control over it. What do we mean?

Discoloration of polyurethane is a natural process that results from the oxidation of the polymer backbone of the finish on exposure to sunlight.

This problem is associated more with oil-based polyurethane coats. So, you can do nothing to avoid this problem for products that have to be exposed to sunlight, unless you use non-yellowing varnish.

Causes

The main cause is the exposure of the polyurethane coat to sunlight. UV rays come from the sun and may react with the finish, causing gradual yellowing.

Aside from exposure to sunlight, moisture can also cause the yellowing of polyurethane coats.

How to fix discoloration on a polyurethane job

Materials you’ll need for repairing polyurethane

- Rag

- Sandpaper (220-grit)

The only real option is sanding the surface and reapplying the polyurethane coat. Some people use ultra-fine sandpapers to remove the yellow tint, but that doesn’t work. (Read our article on the polyurethane tinting process to gain a deeper understanding of how to address such issues effectively.)

Additionally, if your finished product is going to be exposed to intense sunlight, consider using water-based polyurethane over its oil-based counterpart.

Interesting read: Can you polyurethane over acrylic paint?

10. Cloudy polyurethane floors

A cloudy finish, as you would imagine, totally disfigures the wood. It’s just a milky white color extending a wide radius on the finished wood surface.

Causes

Dust particles trapped in polyurethane coat: If dust particles are not fully cleaned after sanding, they may be trapped in the polyurethane coat and appear as a cloud.

Old polyurethane finish: Using an old, substandard, or polyurethane that has expired is one of the reasons for cloudiness in finished products. This isn’t far-fetched, either, as finishes tend to break down as they age.

Cold conditions: Polyurethane should not be applied in extreme weather conditions, especially cold conditions. This causes several problems as the finish doesn’t combine well and may appear cracked or milky.

Insufficient stirring: Poor stirring before applying the polyurethane coat can lead to a cloudy finish. On the other hand, too vigorous shaking can form bubbles on the finished product.

Materials you’ll need

- Mineral spirit

- Sandpaper (220-grit)

How to fix a cloudy polyurethane finish

To fix a cloudy polyurethane finish, you can try lightly sanding the affected areas and then apply another polyurethane coat. If this doesn’t work, you can try stripping the finish off completely and starting over.

For best results, always stir polyurethane before use to ensure that all ingredients are evenly combined. If you’re having trouble getting a smooth finish, you can try adding a few drops of mineral spirits to the mixture. This will help to thin out the polyurethane and make it easier to spread evenly.

Pro Tip: Before trying remedies, ensure that the polyurethane coat has fully dried. Water-based polyurethane may appear milky before it dries, but the milky color disappears when dry.

Related read: Best way to put polyurethane on wood floors.

11. Blushing

Blushing is characterized by the presence of a milky haze in the polyurethane finish.

If this sounds familiar, it’s because it is – remembers the cloudy finish?! However, blushing is different because it is not nearly as extensive in size. It’s like a distant relative of cloudy finishing, and they have mostly different causes too.

Causes

Droplets on the finish: This is in two ways. Firstly, some polyurethane finishes dissolved in solvents may suffer from blushing because the solvent used evaporates rather quickly from the wood surface.

This evaporation can cause a drop in temperature that condenses water, which is trapped in the polyurethane coat. However, this is not common with polyurethane because the finish dries relatively slowly compared to other paint finishes.

Secondly, and the more likely cause with polyurethane, is allowing droplets or other wet objects to remain on the wood surface for an extended period.

Using incompatible finishes: The two main finishes for polyurethane are oil-based and water-based. They both have their areas of specialty.

One mistake many make is using both these coats on the same surface. Water and oil don’t mix, so it’s no surprise this combination can cause a problem like blushing.

How to fix blushing on a polyurethane job

Materials you’ll need

- Rag

- Alcohol

- Sandpaper (180-grit)

Step 1: Clean the affected areas with a rag dampened in rubbing alcohol. You can do this twice to limit the apparent damage of the blush.

Step 2: Sand the wood surface until the wood appears dull.

Step 3: Reapply the polyurethane coats.

12. Orange peel effect

The orange peel effect on polyurethane jobs gets its name from the high semblance of the finished wood with an orange peel. The surface of the wood is usually rough, like an orange peel.

It is common when rollers are used to apply the finish in the place of brushes. This problem results from the polyurethane finish not leveling before it dries, causing rough, thick coats.

Causes

The orange peel effect is associated with coating in very cold conditions or polyurethane roller application.

This doesn’t mean a roller will always cause the orange peel effect, but the chances of having this deformity when using a roller are far higher.

How to fix the orange peel effect on a polyurethane job

Materials you’ll need

- Rag

- Sandpaper (220-grit)

The only way to fix the orange peel effect is to sand the affected surface and reapply the polyurethane finish. It is unfortunate, really, but there are no other fixes.

However, there are precautions that you can take to ensure the orange peel effect problem doesn’t arise at all. One of such precautions is ensuring you work in average conditions.

Extreme weather conditions will interfere with the integrity of the polyurethane finish and, ultimately, the coating process. Also, stick to brushes and sprays to significantly lower the chances of the problem occurring.

13. Dried finish

After some time, the polyurethane coat may get extremely dry. The coat doesn’t stick to the wood surface anymore. And it may not happen all across the furniture; instead, one region may get very dry while its environment seems perfectly fine.

Causes

The most typical cause is old age. Just ripe old age. Of course, some finishes will last longer than others, but the polyurethane coat usually weakens as it ages.

However, furniture owners may accelerate this process by exposing the wood surface to extremely hot and dry conditions.

Restoring polyurethane finish that has dried

Materials you’ll need

- Rag

- Mineral spirits

- Sandpaper (340-grit)

Here’s how to restore the polyurethane finish

Step 1: Sand the surface and clean thoroughly with a rag

Step 2: Apply the polyurethane coat. For oil-based polyurethane, you may first need to thin with mineral spirit.

Step 3: You can apply more coats on the base coat. The more coats you add, the less need to thin the polyurethane finish. However, all sanding must be limited to coats beneath the topcoat.

14. Peeling

While it is unwanted, it is not an unfamiliar sight for a polyurethane coat to start peeling.

This means some regions of the polyurethane finish completely lose their attachment to the wood surface and get very loose. It is truly an uncomfortable sight to look at.

Causes

Dirty surface: Before coating, cleaning the wood surface of all debris and particles is necessary. One of the implications of coating a dirty surface is the polyurethane coat peeling off after a while. This is not unexpected, too, as the coat finds it difficult to stick to the wood surface.

Thick coats: Applying overly thick coats is never a plus in polyurethane coating, and peeling of the finish is another problem that proves that.

If the coat is too heavy or thick, the chances of sticking tightly to the wood and one another are slim, eventually causing the coat to lose its adhesiveness to the wood surface or base coat.

How to fix peeling on a polyurethane job

Materials you’ll need

- Rag

- Sandpaper (320-grit)

- Paint stripper

The best approach to fixing peeling is to first strip the surface of the polyurethane coat. You can do this by applying a paint stripper to the polyurethane coat, which makes it easy to remove.

This is followed by sanding the surface and then reapplying the new polyurethane coat.

15. Runs or too much polyurethane

Runs are a problem common to slow-drying finishes like polyurethane. It looks like droplets of the polyurethane finish have run down without blending with the rest of the evenly spread paint.

If it dries, any attempt to remove it will result in a deformation of the finished surface.

Causes

The main cause of runs in a polyurethane job is the applying too thick coats or too much polyurethane without uniformly spreading the coat. The excess droplets slowly dry as they trickle down, causing runs as we know them.

Materials you’ll need

- Rag

- Sandpaper (220-grit)

How to fix runs in polyurethane finish

If the runs have not dried, use the brush to apply excesses in one region to another region. This spreads out the polyurethane finish.

You need to level it by scraping or sanding in cases where the runs have dried. Note that you should only do this when the runs have solidified enough. You will only make a mess if you try to sand runs that have not fully hardened.

Step 4: After leveling the runs, reapply the polyurethane coat with a rag.

Tips on Applying a Polyurethane Coat Correctly

Knowing how to fix problems is good, but avoiding these problems – is even better! Below are crucial tips and precautions for quality polyurethane coating.

- Do not work in extreme temperature conditions. This means you should only work at warm temperatures.

- Stir the polyurethane finish before use, but do not vigorously shake the can when stirring the polyurethane finish.

- Ensure you only coat on a clean and smooth surface.

- While brushes are the best finish applicators, ensure you only use quality brushes with fine bristles.

- Do not mix different polyurethane finishes in their respective cans or on the wood surface.

Now that you know how to fix a bad polyurethane job, find out find out how to apply polycrylic to painted furniture.

FAQs

How to fix polyurethane drips

To fix polyurethane drips, you first need to remove the excess material from the surface. You can do this by sanding it down with fine-grit sandpaper. Once the excess material is removed, you’ll need to wipe down the area with a clean cloth to remove any dust or debris.

How to fix polyurethane mistakes?

To fix polyurethane, you can do the following:

- Sand before application

- Re-apply a new polyurethane finish

- Avoid exposure to extreme weather

- Clean your surface prior

- Follow all the guidelines on the label.

Polyurethane finish problems

- Bubbles

- Puddles or polyurethane too thick

- Streaking

- Cratering

- Alligatoring – polyurethane cracking

- Surface Roughness

- Scratches

- Trapped organisms

- Discoloration/ blotchy polyurethane finish

- Cloudy polyurethane floors

- Blushing

- Orange peel effect

- Dried finish

- Peeling

- Runs or too much polyurethane

How to fix uneven polyurethane finish on floor

To fix uneven polyurethane finish on floor, first sand the uneven finish with fine-grit sandpaper. Then, apply a light coat of polyurethane to the sanded surface and let it dry. Check if the coat is even by looking at the thickness or thinness. If the coat is too thick or thin, repeat the steps. (Find out how to remove polyurethane from wood floors.)

How to fix milky clear coat on wood

You can fix milky clear coat of wood by simply letting it dry, as one common cause of milkiness occurs if the polyurethane is still wet. Another way is spreading a thick coat of lemon oil or petroleum jelly onto the affected area. The milkiness should disappear soon after trying these steps.

Also, find out how to clean a polyurethane brush in our guide.

Final Thoughts on Fixing Polyurethane Finish

Polyurethane looks splendid when appropriately applied. Unfortunately, many issues prevent its proper application.

We have highlighted 15 of these problems and proffered the necessary solutions. The ultimate fix for all problems is sanding the surface and reapplying the polyurethane coat.

What next? Dive into our article detailing the process of finishing your table top with polyurethane.