Over the last few years, the use of plexiglass has steadily increased as an alternative to glass. That doesn’t surprise us, considering its shatter-resistance and overall quality.

Wooden furniture like picture frames, shed windows, display cabinets, and cupboards commonly have plexiglass glued to them.

Despite the recent uptick in their use, many still don’t know how to glue plexiglass to wood. If you fall in that category, you have come to the right place! Here, we will examine the steps to properly glue plexiglass to different wood surfaces.

How to Glue Plexiglass to Wood

While gluing plexiglass to wood may appear easy, the bonding process should be carried out adeptly to prevent chipping. You will need certain tools to secure this bonding.

These include:

- Drill bits and drilling machine

- Sandpaper

- Marker pen

- Masking tape

- Clean cloth

- Clean Plexiglass or acrylic sheet

- Wooden item

- Contact cement or other adhesives to glue acrylic glass to the wood surface

Step 1: Choose a suitable workspace

Before you start, select a solid workspace, as it will profoundly affect the outcome of your task. It is advisable to carry out the preparatory work in a satisfying workspace.

Your workspace should be made of either wood, metal, or concrete. We recommend using brown wooden boards for a wooden workspace. Using glass or paper materials would be a bad idea as plexiglass can adhere to them.

Getting together the right materials will help improve your work. Some glues, like the ten-ounce glues in sealed tubes, require the use of a caulk gun.

You’re on the right track as long as you can dispense these construction-grade adhesives properly at the right pressure.

Placing a canvas drop cloth to protect the work surface would be a good idea in case of spills. You can also protect the work surface by masking off the areas you don’t want to glue with the aid of blue painter’s tape.

Step 2: Mark the edges of the plexiglass

After setting the plexiglass on a flat surface, mark all corners of the plexiglass with a marker pen, preferably black. Make sure these markings are as precise as possible.

These marked spots will serve as the pre-drilled holes for installation on the wood, leaving a gap of at least an inch from the edge of the plexiglass to prevent the drill bits from reaching the edge.

That can lead to an unwanted result, possibly damaging the material.

Step 3: Cut desired lengths of plexiglass

This step is discretionary and applies to anyone who wants to cut the Plexiglass sheet into smaller pieces. To cut the plexiglass sheets into desired lengths and sizes before attaching them to the wood, measure and mark the cutting line along your straight edge.

You can then cut into proper sizes and shapes with your cutting instrument. As we mentioned earlier, you would like a suitable workspace to carry this out.

Further, you have to factor in the thickness of your plexiglass sheet and the type of wooden surface before cutting. The wooden surface can be either horizontal or vertical.

For instance, a thick acrylic sheet that is a quarter-inch (6.3mm) or thicker is best cut with a table or miter saw. You can easily snap thinner sheets apart with a utility knife. However, your cutting lines should be as precise as possible.

To ensure that the plexiglass will be properly glued to the wood, you may need to smoothen the joints. Using high-caliber sandpaper, smooth out the rough surfaces and wipe out the dirt created in the process before cleaning.

Step 4: Clean the plexiglass

You should note that before you glue plexiglass to wood, the surface of these substrates must be free from oil, grease, dirt, and dust deposits.

Therefore, a thorough cleaning using mild soap or rubbing alcohol such as isopropyl alcohol is essential. Concentrate on the edges of the plexiglass that will be glued to the wood as they will be the points of contact.

The presence of unwanted dirt would affect your work. After cleaning, blot the pieces of the Plexiglass sheet to dry with the aid of a clean cloth. Ensure that you do not rub the surfaces to prevent scratching.

Step 5: Position the plexiglass on the wood

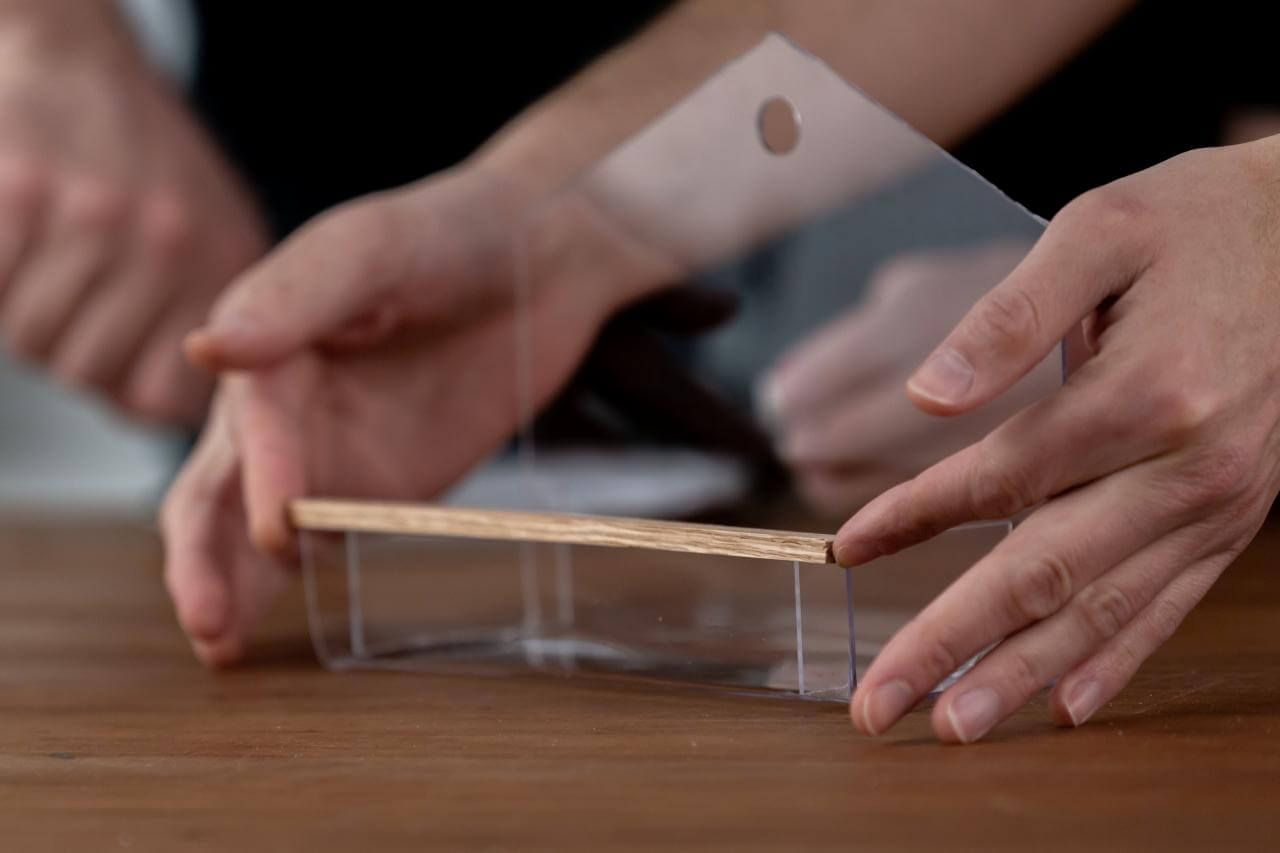

Once you have cleaned all parts and inspected them to check for unlikeness, assemble the pieces of the plexiglass sheet.

After assembling and ensuring a tidy fit with a masking tape or clamps, position the plexiglass on the wood where it will be installed.

Step 6: Apply the glue

When you have positioned the plexiglass on the wood, you can apply the glue using a wood glue bottle. Before using the glue, ensure that you have an adequate amount for the entire project.

You can’t afford to run out of adhesive and have to use an alternative. Different glues have different directions and procedures for use. Please check the specified manufacturer’s recommendations before use.

The best method of applying the glue to the plexiglass is using a syringe, preferably a 25-gauge syringe. Why syringes, though?

Syringes are water-thin and work by melting the clean acrylic glass to bond the sheets together following a chemical reaction. Also, you can apply a considerably small quantity of glue between the pieces of the plexiglass.

There are precautionary measures to observe while applying the glue, and they include:

- Wear protective kits such as rubber gloves and safety glasses

- Ensure the pieces are well clamped before applying the glue

- Spread the glue uniformly over the exterior of the plexiglass

- Be careful not to apply on any other surfaces

- Apply the glue at once and avoid pressing as the pressure applied can deform the plexiglass as well as trigger weaker joints

- Use the syringe in your direction rather than pushing it away

Step 7: Attach the plexiglass to the wood

After applying the glue to the plexiglass, attach the formed plexiglass to the wooden surface while ensuring that both exteriors are lined appropriately.

Mount the plexiglass to wood glue. Then, apply substantial pressure along the entire cover of the plexiglass so that it sticks firmly to the bottom layer.

For best results, do this after the adhesive has been allowed to set or dry for the specified time to ensure a good bond.

Step 8: Allow glue to dry

The last step is to allow the glue to set for the specified amount of time. One crucial detail – different adhesives require different times and temperature conditions to secure a stable and firm adhesion.

So, check through the glue’s manufacturer’s guide before use. Ensure your plexiglass design stays unagitated once affixed until the glue has dried.

Moving it during drying may cause the layers to separate, resulting in an unwanted result. After the drying time elapses, you can remove the clamps or masking tapes you used to clutch the pieces together.

Best Glues for Attaching Plexiglass to Wood

It is essential to identify the appropriate glue for gluing plexiglass to wood. Not all types of adhesives can bind plexiglass to wood.

You can use any of these four best types of glue to suit your needs:

1. Superglue

Superglue is one of the default adhesives to bind various materials together easily. Superglue, a type of cyanoacrylate adhesives, is accessible in liquid and gel forms. It can provide a tight, solid bonding, and remain very dry when properly used.

How Will Super Glue Help Bind Plexiglass to Wood?

First, does super glue work on wood? Yes, due to its unique formulation, Super glue can serve as a special multi surface adhesive to bind the plexiglass sheets to wood.

This solvent cement can form a strong, solid white layer and can stay dry as long it is placed in a dry, low humid environment.

However, the solvent cement melts in unfavorable storage conditions. Its viscosity provides more tolerance for gap filling, making the cyanoacrylate glue a good adhesive for woodwork.

Conjugating super glue with saw specks of dust makes the attachment a lot better. These specks of dust will help fill small holes.

The steps below show how you can successfully add superglue to glue glass to wood.

step 1: Super glue is sensitive to the amount used and the amount of contact. Generally, the glue will not adhere correctly if the surfaces are not appropriately mounted. Thus, ensure that the plexiglass and the wood surfaces are fit.

step 2: You should wear a mask and protective gloves when using a large amount of super glue dissolved with solvents to avoid a messy result.

step 3: Super glue sets in seconds depending on the formulation. However, note that the glue will not adhere quickly to dry wood, unlike other acrylic adhesives. Ensure you apply the glue when the wood is mildly wet to obtain a good glue surface.

2. Acrylic adhesive

If you are familiar with the adhesive industry, you will likely have come across acrylic glue. However, the term is loosely used. An acrylic adhesive is a water-based resin adhesive material composed of acrylic polymers.

Like superglue, acrylic adhesives are made available in liquid and gel form to bond various objects together. Additionally, they are very environmentally resistant, and as a result, they are the preferred option in the construction industry.

Furthermore, acrylic adhesives are characterized by fast, easy adhesion with superior bonding strength. These adhesives aim to provide better design diversity, easy application, resist pressures, and improve throughput and productivity.

How Do You Glue Plexiglass to Wood With Acrylic Adhesive?

- To start with, consider the thickness of your materials. While acrylic adhesives are well known to provide relative permanence in bonding, applying inadequate amounts can affect the design.

- Also, temporary acrylic adhesives are characterized by lesser cohesion and adhesion; thus, you can easily snap them apart. You must identify the adhesive suitable for your project.

- Acrylic adhesives in a liquid form can be applied to dry wooden surfaces, unlike the superglue. Another use style is in combination with the gel form for even stronger bonding.

The acrylic glue is the ideal adhesive for attaching plexiglass to wood surfaces.

3. Acrylic Silicone

The difference between acrylic silicone and other acrylic adhesives is not far-fetched. The silicone sealant is based on silicone polymer.

The Silicone sealant is renowned for its permanent flexibility and superior adhesion strength. It is perfect for materials in direct contact with water. This is due to the sealant’s ability to maintain flexibility at ranging temperatures.

How to Apply Acrylic Silicone?

A major character in the application of acrylic silicone is due to their waterproofing properties. These waterproof glue for wood also have excellent resistance to external climate conditions.

You can adhere acrylic silicone to wood in the same manner as acrylic adhesives.

4. Epoxy Glue

Epoxy glue is a synthetic adhesive composed of a mixture of epoxy polymer and a hardener used to bind various materials.

The resin glue or the epoxy polymer and the hardener can be packaged separately in a box of the wood glue as a two-part or already mixed as one part.

Epoxy glue forms a tight, resilient bond to withstand extreme climatic conditions. It is important to note that these substances should be mixed only when you are ready for gluing. You should also mix on a 1:1 ratio to avoid cross-linkage.

Read also: What is the best epoxy resin for tables?

Is Epoxy Glue Suitable for Gluing Plexiglass to Wood?

Absolutely! The resin glue has excellent adhesive properties; however, for more effective bonding when applying epoxy adhesives, follow the steps below:

- Epoxy glues are non-toxic but ensure you wear a mask and protection gloves to prevent irritation. Remember, safety first.

- Epoxy glues tend to be more effective on rough surfaces, thus ensuring the wooden material is well sanded before applying.

- The resin glues tend to be most effective on clean, dry surfaces, as the presence of contaminants will reduce the strength and integrity of the bonding.

You can purchase these adhesives at plastic supply stores.

Check out this guide on the best deep pour resin, ideal for creating clear epoxy projects up to several inches deep, featuring low viscosity and UV-resistant properties that prevent bubbles and yellowing.

FAQs

Can you glue acrylic glass the same way as plexiglass?

Well, we’d suppose so, considering they’re the same! There have been a lot of misconceptions related to these two terms. Plexiglass is a non-literal way of referring to acrylic sheets. One of the many brands of clear acrylic sheets called Plexiglas gave rise to the popular term Plexiglass. Hence, plexiglass is the same as acrylic.

Can you fix a broken plexiglass?

Fixing a crack in the plexiglass is an easy task. First, drill a fine hole at the edge of the crack, then fill the crack with enough plexiglass adhesive using a glue syringe. Wipe off any excess dripping glue with a dry cloth and allow the adhesive to set.

Do you need to add acetone when gluing plexiglass to wood?

You don’t necessarily need to add acetone when gluing plexiglass to wood. Acetone can dissolve large amounts of glue if not properly dried, causing damage. Acetone is valuable for wiping off the excess adhesive after ensuring adequate drying.

Can you use hot glue to attach plexiglass to wood?

Hot glue adhesive can be used to attach plexiglass to wood as it is suitable for both permeable and non-permeable materials. The characteristic high viscosity of hot glue renders it one of the most suitable glues to attach plexiglass to wood. When using hot glue, ensure you have a bowl of cold water beside you in cases of accidents, and also wear protective gloves.

What is the best wood glue to use for attaching plexiglass to wood?

The rapid strong epoxy adhesive is a synthetic glue that uses two different materials, namely the epoxy polymer and the hardener. When mixed, these two materials create a reaction, forming an extremely durable, stable adhesive bond for attaching plexiglass to wooden surfaces.

The resin glue can also be colored easily, allowing design flexibility. These properties make epoxy adhesive the most suitable glue to attach plexiglass to wood.

Related Post: Best Glue for Wood to Metal

Conclusion

Plexiglass has won a lot of fans in recent times as an alternative to glass. However, you need to know how to glue plexiglass to wood before actually attempting to glue them for the best results.

First, you have to identify the material properties. Further, ensure the surfaces are clean and ready to be attached and then use the appropriate adhesive. Finally, allow them to dry for the specified time.

Do this, and watch your plexiglass couple with your wooden material like the perfect match they were always designed to be!