Charring is an age-old wood coloring and preservation technique that involves exposing wooden boards and planks to an open fire.

Also known as Shui Sugi Ban, it gives the wood a beautiful, rustic feel. Additionally, charred wood is stronger and more durable.

But it helps seal your charred boards for maximum protection. So, below we explain how to best seal charred wood if you decide to burn some of the boards on your next woodworking project.

How to Seal Charred Wood

The most effective way to seal charred wood is to brush down the surfaces, stain the boards, and seal them with high-quality wood sealant. Always use a clean brush, lightly dipped in the sealant, and wipe off excess or thick globs on the brush for a thin, even sealant coat.

What’s Charred Wood?

Charred wood, also known as burnt wood or Shou Sugi Ban wood, refers to wood boards and planks subjected to open fire to burn the wood surfaces lightly.

Charring helps with weatherproofing, surface protection, and pest deterrence. Additionally, charred wood surfaces can be strikingly beautiful.

The Origin of Shou Sugi Ban

Shou Sugi Ban is an ancient Japanese technique for preserving wood. It’s a slight variation of the Japanese word “yakisugi,” which loosely translates to “heating Japanese cedar wood with fire.”

Generally, yaki means “to heat with fire,” while sugi refers to Japanese cedar. Meanwhile, “Shou” means durable, and “ban” means wood plank.

The wood preservation method dates back to the 18th century when Japanese woodworkers burned the outer layer of wooden planks, particularly cedar planks, to protect facades from pests and weather elements.

However, other people later adopted the method to beautify wooden doors and furniture, and soon architects and designers picked up on the trend.

Today, the previously underrated technique is a popular means to preserve untreated wood, add texture to various wood projects, and attain a rustic decor.

Interesting read: Does interior cedar need to be sealed?

The Shou Sugi Ban Process

The wood charring process is as simple as it sounds. All you need is an open fire and your wood planks, and off you go.

Most yakisugi woodworking enthusiasts use a propane torch that generates powerful heat in concentrated areas, burning the outer wood surface to charcoal. It takes 5-10 seconds of burning for the wood to blacken and become covered in soot.

The next step involves using a wire brush or coarse sandpaper to wear down the charred wood’s outermost layer without smoothly sanding it.

Typically, it leaves an alligator-like skin finish with beautiful ridges and bumps. The charred surface may also carry unique patterns depending on the type of wood.

Best Shou Sugi Ban Wood

Traditional Japanese yakisugi enthusiasts mainly consider cryptomeria Japonica (the Japanese red cedar) as the best wood for Shou Sugi Ban.

It’s a highly porous wood that’s easy to char without weakening. Moreover, Japanese red cedar produces amazing surface patterns when charred.

Unfortunately, the Japanese red cedar only grows in Japan and a few Asian countries. So, you must find practical alternatives if living in a different region.

One of the best choices in the western hemisphere is the western red cedar. It resembles Japanese red cedar and boasts similar natural strength and durability. Moreover, it’s a beautiful hardwood with a gorgeous grain pattern.

The next best options if you cannot find the western red cedar are hemlock, southern cypress, pine, and basswood.

Unfortunately, softwoods aren’t great candidates for a Shou Sugi Ban wood project as they can become too weak after heating.

See the battle between red cedar and white cedar woods.

Interior and Exterior Applications

Shou sugi ban has many applications in modern woodworking. Interior applications include interior wall cladding, ceiling cladding, flooring, and artwork. In addition, a growing section of the population has taken to charred furniture.

Meanwhile, the most popular outdoor application is making exterior siding. Again, charring protects the wood while offering numerous patterns and designs.

Benefits of Sealing Charred Wood

First off, you don’t always need to seal charred wood. Indeed, traditional yakisugi enthusiasts from native Japan don’t seal burnt wood. All they do is work down the surface to the desired color depth and texture – that’s it.

However, sealing benefits all wood, including Shui Sugi Ban. The following are a few reasons you may want to seal your charred items;

- Protect the wood surface: Sealing provides an extra layer of protection over the charred wood surface, shielding it from weather and everyday wear.

- Beautify the wood project: A coat of sealer over any wood project enhances the item’s aesthetic appeal.

- Adds a waterproofing layer: Charred wood is not necessarily waterproof. So, you need additional means to waterproof it. A sealer coat protects Shou Sugi Ban items from rain and water spills.

- Provides the perfect foundation for additional finishes: You need to refinish wood projects severally over their lifespans. The right sealant provides the perfect base for future finishes.

Now, let’s compare sanding sealer with polyurethane and evaluate their distinct characteristics and applications.

Choosing the Right Sealant for Charred Wood

Assuming you’re convinced of the benefits of sealing your burnt wood projects, the next step is to find the right sealant for the job. You have endless options. However, the best three choices are;

1. Best traditional wood oil for charred wood – Sunnyside Corporation 87332 Pure Raw Linseed Oil

- Penetrates deep and protects wood creating a quality finish for wood furniture and antiques

- Apply to raw wood only

- Increases water repellency and weather resistance

Traditional wood oils like linseed oil, teak oil, and tung oil are some of the best choices for sealing Shou Sugi Ban projects. The plant-derived oils provide a natural finish without environmental harm.

Moreover, they lock in the original color of the Shou Sugi Ban while deepening the appearance of the wood grain. Our favorite is Sunnyside Corporation 87332 Pure Raw Linseed Oil.

This natural wood protector shields wood projects from water, weather, and wear. It also fortifies wood, extending its lifespan. Above all, pure raw linseed oil adds a natural gloss to wood surfaces.

If you’re wondering, boiled linseed oil is another good choice. However, raw linseed oil provides the purest form of linseed oil power. The only downside is that raw linseed oil takes longer (typically 2-4 days) to cure fully.

Pros

- Natural oils are all-natural

- Help enhance the wood grain

- Bring out the nuanced colors of burnt wood

Cons

- Not very durable (requires reapplication every 1-10 years)

- Natural oils don’t provide much UV protection

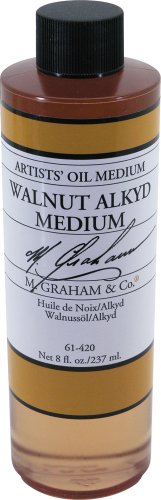

2. Best alkyd oil for charred wood – M. Graham 8-Ounce Walnut Alkyd Medium

- Thins the color and accelerates drying and enhances adhesion between layers

- Increases surface sheen and flexibility while remaining non-yellowing

- Increased flow allows more control over all types of painting application

Alkyd oils provide long-lasting protection. Indeed, they’re longer lasting than natural oils, requiring applications every 2-15 years. Moreover, they are plant-derived oils, albeit chemically altered.

We also love that they provide excellent UV protection. This makes alkyd oils a great choice for exterior Shou Sugi Ban applications. Our favorite choice is M.Graham 8-ounce Walnut Alkyd Medium.

The multicolor formulation is a fast-drying solution that enhances adhesion between layers while increasing sheen and flexibility. It’s also a free-flowing formula that offers great control over all wood surfaces.

The non-toxic, solvent-free sealant is the perfect choice if you prioritize longevity over aesthetics. You’ll appreciate that it doesn’t yellow over time.

Pros

- Provides a long-lasting finish over Shou Sugi Ban

- It fades slowly and into unnoticeable patterns

- Doesn’t yellow over time

Cons

- It’s not completely natural

- It’s not very easy to find in local stores

3. Best polyurethane sealant for a charred surface – Rust-Oleum 200061H Water-Based Ultimate Polyurethane

- Protects indoor wood surfaces such as furniture, windows, cabinets, trim and more

- Water based formula dries fast and cleans up with soap and water

- Dries to the touch in 30 minutes with coverage up to 31.25 sq. ft., recoat after 2 hours

Finally, you can always turn to polyurethane for your wood sealing projects. Both petroleum and plant-derived products work excellently on wood surfaces.

They amplify the wood’s shine while protecting the surface from dust, sunlight, and other elements. Polyurethane also offers excellent protection outdoors, protecting wood projects from rain, UV, and other factors.

Our favorite polyurethane sealant for Shou Sugi Ban wood is Rust-Oleum’s water-based Verathane Ultimate Polyurethane.

The clear-gloss sealant forms a polished and clean layer that protects indoor surfaces like windows, cabinets, and furniture from stains and scratches.

Moreover, it’s a water-based formula that dries to the touch in 30 minutes. A wide 31.25 sq. ft. coverage for every 8Fl Oz (half a pint) makes it one of the most economical sealants for Shou Sugi Ban applications.

NB: Shellac sealant is another excellent choice for sealing indoor Shou Sugi Ban projects. However, don’t use it for outdoor wood projects as it doesn’t respond well to humid conditions.

Sealing Charred Wood

Requirements

- Wood sealant

- Wood stain

- Brushes

- Air compressor

- Vacuum cleaner

- Rags

How to Seal Shou Sugi Ban Siding: Step-by-Step Guide

When you’re ready to seal charred wood, find an open space to avoid intoxication. Then follow the three steps below;

1. Brush down the wood

Pick up a wire brush and gently brush down the wood. Brushing the wood does a few things. First, it cleans the wood. This is critical for all woodworking projects.

It removes dust and debris clinging onto the wood surface that may hamper the quality of the finish. Secondly, brushing down the surface helps to even it out. An even surface increases project value and makes it easier to apply the finish.

You can brush it a little more to reveal a brownish-black color underneath. However, most people prefer the charcoal-black appearance.

Similarly, a coarser wire brush removes paint and wears down the surface into a smoother texture. The choice is yours. However, always work along the wood grain.

2. Clean up the surface

After brushing it down with a wire brush or sandpaper, the next step is to clean the wood surface to eliminate dust particles that may become trapped under the sealant.

Trapped dirt and debris create adhesion problems, often causing sealants to wear off faster. They can also cause surface inconsistencies.

We recommend a two-step cleaning process. First, use an air compressor to blow away the tiny dirt particles. Alternatively, use a low-power vacuum cleaner.

Next, wipe down the entire surface with a wet cloth. Tack-free clothes work best because they don’t introduce new debris to the surface.

Alternatively, wash it down with mild soap and warm water. Avoid harsh cleaning agents, though. Then allow the surface to dry completely before moving to the next step.

3. Stain the wood (optional)

Many people are happy to seal charred wood as-is without staining or painting. The black or brown-black color provides perfect tones for a rustic finish.

Alternatively, you can use it to achieve a farm-style setting or add color and texture to modern decors. However, a thin coat of stain is another option.

It gives the wood a new color while providing additional surface protection. For instance, you can choose a weatherproof stain to increase the weather-resistance properties of outdoor Shou Sugi Ban pieces.

Finally, some people love a bold coat of paint. If so, you can paint the wood before sealing. Make sure to apply a thin layer of stain or paint for maximum adhesion and durability.

4. Seal the wood

The last process is applying the sealant, which is no different than sealing normal wood or furniture. Begin by getting a new brush for the sealing process because using the same brush for staining and sealing can mess up the project.

Then when ready, dip the brush into the sealant, remove the excess sealant, and gently apply the sealant over the surface.

One coat of sealant is often sufficient. However, you can apply a second coat if the first one isn’t even. If so, wait for the first coat to dry completely before applying the second one.

You’ll find the manufacturer’s specific directions on the product label. Otherwise, let the first coat dry for three hours before the second one.

You might be interested to read: Best sealer for outdoor painted wood.

Tips and Tricks When Sealing Charred Wood

Sealing charred wood is a straightforward process, as you have seen. However, challenges like poor adhesion, uneven drying, and inconsistent finishes are common if you’re not careful.

Three important tips can help you avoid these issues;

1. Test before you start

Before applying the stain and sealant over the entire board, test them on a small area. This will tell you whether the combination of finishes will give you the best results.

It also reveals potential issues beforehand, allowing you to prevent them in the first place. The best place to test the stain and sealer is an inconspicuous area of your burnt wood.

For instance, a small area of the siding close to the ground is perfect. Follow the same steps you’d use during the actual sealing. Then wait a day to see if the products give the best results. If so, proceed to seal the entire surface.

Read also: Can you put Thompson’s water seal over a stain?

2. Less is more when sealing charred wood

Too much of anything can be dangerous when sealing burnt wood. This applies right from the brushing stage to the sealing process.

Choose the right wire brush and begin with light scuffs to smooth the surface. Then go over the entire surface again if you’re not satisfied. This is safer than digging into the wood in one section only to end up with an uneven surface.

The same wisdom applies when staining and sealing. Don’t pick up too much stain/sealant with the brush. Instead, apply thin, even strokes and apply a second coat if needed.

3. Work in a well-ventilated area

Proper ventilation when sealing burnt wood is critical for your health and to achieve a high-quality finish. First, proper ventilation helps to pull out toxic fumes that may cause breathing issues and lung disease.

This is particularly important when using polyurethane sealants that produce a strong odor. Secondly, you need the right balance of temperature and humidity for the stain and sealant to dry evenly and properly.

Therefore, it’s best to work outdoors in the open. If not, open the windows and doors and wear a breathing mask.

Related read: Sealing MDF before painting.

FAQs

What kind of oil do you put on burnt wood?

You can use most natural wood finishing oils on burnt wood. These include linseed oil, tung oil, and hemp oil. These oils soften the sheen and improve the surface’s weather protection. Moreover, the oils usually harden to a durable coating after prolonged air exposure, increasing the item’s lifespan. Reapply the oil every 10-15 years for the best results.

What do you seal Shou Sugi Ban with?

The best sealant for Shou Sugi Ban wood is natural oil. First, spray the ash and dust away using an air compressor. Then wipe down the charred surface using a wet cloth and allow it to dry. After that, apply your favorite natural oil to seal the surface. A petroleum-based or plant-derived polyurethane sealant is another good choice for indoor Shou Sugi Ban items.

Does charring wood waterproof it?

No, Shou Sugi Ban alone doesn’t waterproof wood. So, you must not rely on it for surface waterproofing. That said, burning wood always makes wood slightly resistant to water and moisture penetration on a cellular level. In addition, burning the top wood layer transforms it into char (carbon) that doesn’t rot and is more water-resistant than regular timber.

Related: Wood for wood burning projects

Summary

Shou Sugi Ban is one of the best ways to preserve wood while enhancing the project’s aesthetic properties.

However, you should strongly consider a wood finish to protect the surface from external elements. Charred wood sealants do this excellently while highlighting the surface’s color and grain.

If you’d like to know how to seal particle board edge, read our other comprehensive guide.