For some time, particle board has proved to be a very useful building material for several home construction projects. You might have used or want to use it as a kitchen countertop or an interior cupboard in your home.

The first thing you need to know is particle boards get easily ruined by moisture which is why they need to be sealed or waterproofed.

We’ll discuss how to seal particle board and reviews some of the best particle board sealers.

Let’s dive right in;

How to Seal Particle Board

Using a paintbrush, you can seal particle board by applying a coat of waterproof or clear acrylic sealant over all the edges of the board and other areas more exposed to moisture. You can also add additional coats of the sealant for proper sealing.

Why Should You Seal Particle Board?

A particle board is modified wood made from wood chips and resin mixed and dried to form a board. It is not as strong as most hardwoods used in construction; hence it has to be made durable to last over the years without breaking or warping by using a sealer.

For instance, particle board cabinets are especially exposed to moisture.

There are several other reasons why you should seal particle board after installing it, but here are a few of them:

- Rain and excess heat can damage particle board, so if you use one in an outdoor space, it is important to seal it.

- Before a particle board that has been previously used to be effective for use again, it needs to be sealed.

- After a board gets damaged, applying a sealer is probably the only way to fix it for further use.

- The particle board also needs a sealer to bear some weight without damaging it.

What is a Particle Board Sealer?

A particle board sealer is mainly used for waterproofing and other purposes. It will do the job well if the board’s surface is clean.

Not all sealers used on regular solid wood can be used on particle boards due to their wood material, so specific types are formulated for them. Generally, clear solvent-based sealers are best as they are volatile.

Types of Particle Board Sealers

There are two basic types of sealers that can be used on particle boards. They are described below:

Polyurethane

This is a particle board sealer made of polyurethane. Now polyurethane is one of the popular finishes used on wood, and it comes in two different kinds:

- Oil-based polyurethane

- Water-based polyurethane

The obvious difference between water-based and oil-based poly is their composition, but they both have pros and cons. An advantage to the oil-based type is that it gives more protection, making it a better outdoor option.

On the other hand, water-based dries faster and is more suitable for indoor use. It is important to know the kind of polyurethane sealer you are about to use as the application processes differ.

For instance, oil-based types require being mixed with an oil-based thinner before spraying on the board, whereas you can apply the water-based type in thin coats with a brush.

Epoxy resin

This type of solvent-based particle board sealer can come in two different forms. One can be used straight out of its container, while another requires mixing with another solvent before it can be used.

It is not as commonly used as polyurethane, though.

Functions

There are uses of particle board sealers that you should know. They include:

Making the particle board durable

Just like any sealer makes the item more durable, particle board sealers also do this. They protect the boards from cracks or warps due to long exposure to extreme weather conditions, especially when used in certain house areas.

Saving the particle board from sun and water

Unlike a stained particle board, a sealed board is safer from hard elements. After it is dried, the sealer serves as a hard covering that protects the particle board from water or heat from the sun penetrating. So your board gets protected from exposure to these.

Strengthen the particle board

Sealing makes the particle board strong enough to carry weight. To an extent, particle board sealer helps strengthen the board, so it does not get damaged easily.

A plus to sealing your board as well is you do not have to be extremely careful about where you want your board installed or used.

Enhances usability

Another advantage of using a particle board sealer is it makes your board more versatile. So you not only get a stronger and more durable board but one that you can serve various purposes.

Seal Your Particle Board in Four Easy Steps!

Now, if you want to seal your particle board, ensure you are doing it right and have a properly sealed board before installation. The sealing process is quite easy to follow, and the steps involved are explained below:

Tools and materials needed

The tools and materials you would need include:

- A saw

- Paintbrush

- Sealant

- Measuring tape

- Marker

- Safety Goggles

- Mask

Steps

Safety first

Remember, the wood chips particle boards are made of can easily get into the air and hurt your eyes or nose.

Hence, you must wear your mask and safety glasses first so the chips do not get into your eyes or nose. So before you begin doing anything, you want to take this safety precaution first.

Step 1: Measure the particle board

This step is important as you need to know the size of board you are working with to know the amount of sealer you use.

First, use a marker to mark the areas where the particleboard will be installed. Then use a measuring tape to measure the marked area’s height and width. Transfer the measurements to the particle board using the same marker before cutting out.

Step 2: Cut the board

The next step is to grab a circular saw or jigsaw to start cutting out the board. You want to be patient while you cut out the particle board pieces so you do not miss the dimensions.

You also want to ensure you are protecting yourself from all the board chips flying around as you cut and are careful not to hurt your hands with the saw. Give the board a good wipe to have a clean surface after this.

Step 3: Apply the sealant

After you cut out the board you want to work with, the next step is to apply the sealant. Depending on which one you want to use, ensure you read the instructions on the container before you begin the application.

So you might have to shake the can or stir the formula well, so it is properly mixed before use. Use a small paint brush or paint rollers to apply the sealant evenly around all four edges of the boards.

Then if you need to apply a second coat, you need to use a bigger brush.

Step 4: Allow the sealant to dry

After applying an adequate amount of the sealant you need, it is important to allow it to dry totally. You can get a particle board step proper storage for it to dry naturally there.

A hairdryer can also make the drying faster but be careful not to use it at a very high temperature. Once the sealant has dried, you have your completely sealed particle board ready to be installed.

Related read: How to Seal MDF Before Painting.

Best Sealer for Particle Board

So, we found three best-selling particle board sealers on Amazon that will give you that waterproof particle board you need. The products are described below as well as their review.

1. RainguardPro MICRO-SEAL

- PROFESSIONAL WATER REPELLENT: Protect, restore, and extend the life of your project with RainguardPro MICRO-SEAL! Formulated to penetrate deep into the surface, MICRO-SEAL is a breathable silane/siloxane water repellent that helps inhibit efflorescence, lime, spalling, and other moisture damage. This pro-grade multisurface sealant is safe to use indoors or outdoors. It dries to an invisible stain resistant finish that won't yellow or alter surface texture or appearance.

- LONG LASTING PROTECTION: Engineered with Micro-Lok! This proprietary ingredient ensures sealer absorption and creates a long-lasting filmless hydrophobic barrier against weathering, salt, dirt, freezing temperatures, UV light, wind-driven rain, and other damaging elements. RainguardPro MICRO-SEAL is the ideal weatherproof sealer for all porous wood and masonry surfaces including, concrete, brick, pavers, wood, stone, unglazed/unpainted tile, and color integrated or unpainted stucco.

- PREMIXED FORMULATION: Ready to use right out of the bottle! RainguardPro MICRO-SEAL is premixed for easy and convenient application. Before use, shake bottle lightly to disperse any settled material. Perfect for small, medium, and large surfaces, one gallon of this impregnating wood and masonry waterproofer coats, seals, and protects up to 300 square feet. Try RainguardPro's concentrated and super concentrated formulations for a more cost-effective solution.

The name of this product speaks for one of its major functions, which is to protect whatever item you use it on from rain. MICRO-SEAL is a professional siloxane water repellent that helps to keep moisture damage in check.

It is very good when using particle boards outdoor or in areas exposed to harsh weather and rain. It is also safe for use indoors. Rainguard PRO has evolved over the years in its formula.

Now, asides from drying to an invisible finish, its solution is also ready to use so that you can apply it straight from the bottle. This is a good buy if you do not want to deal with a paintbrush to apply your sealer.

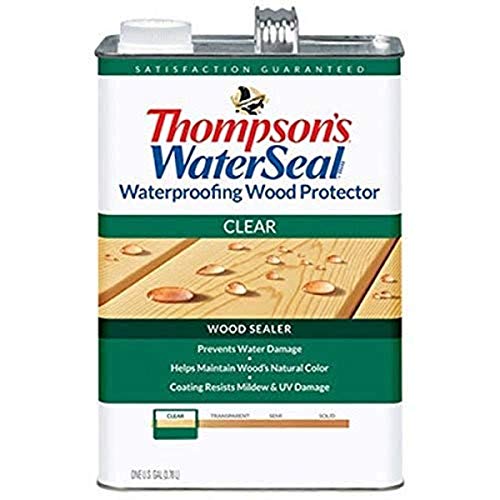

2. THOMPSONS WATERSEAL 21802 VOC Waterproofing Wood Protector

- Item Weight: 9.65 lb

- Country of Origin: China

- Brand name: Thompson's Water Seal

First of you need to know how to apply Thompson’s water seal with sprayer.

The Thompson waterseal is a clear wood protector that is a waterproof sealant as well. It offers long-lasting moisture resistance for particle boards without altering their original color.

Thompsons’ water seal also protects wood from UV damage and mildew buildup over the years, making it an excellent choice for exterior purposes. A downside to this product is it’s quite on the expensive side and can be rare to find.

3. ToughTimber Wood Sealer Water Repellent

- TOUGH TIMBER PREMIUM WOOD SEALER - High End/Industrial Grade Wood, Roof, and Deck Sealer proving protection for years to come! Making your Deck, Wood, Cedar Roof, Cedar Shingles, and Wood Fences water repellent. ToughTimber penetrates deep within the wood for BEST protection.

- PROTECTION - Silane/Siloxane penetrates deep into the wood reducing wood water up-take by 95% protecting it against the elements and preserves the wood for longer periods of time.

- COVERS UP TO 1,000 SQFT (MAKES 5 GALLONS) - Same day, one coat application. Goes on cloudy and dries clear with a slight gloss sheen.

This outdoor wood sealer provides protection for years by preventing water absorption with just a coat. It is also formulated for various wood types, from high-end grade wood to cedar roof, making it one of the best particle board flooring or subfloor sealers.

Moreover, it offers the best protection for outdoor wood furniture, ensuring lasting durability against the elements.

It is also good for getting rid of wood moisture for up to 95% of it and protecting the board from extreme heat. Although it requires being mixed with water before application, it leaves a little gloss sheen on the surface it is applied to after drying.

So if you are dealing with a large area of particle board, this is an economical buy as a gallon is enough for up to 1,000 sq. ft.

Can Wet Particle Board be Repaired?

Yes, a wet particle board can be repaired, but you have to be careful and be sure you know how to so you do not end up damaging the board.

Remember, water is bad for particle boards, so you want to take extra care while trying to repair wet particle boards.

How to Fix Wet Particle Board

Fixing a wet particle board is not difficult, especially when it is a small wet or damaged area that has been affected by water. It can be done in these easy steps:

1. Drying

The first thing you would naturally do to repair wet particle boards is to dry the affected area. You can let it dry naturally or hasten the process using a hairdryer.

Be careful not to use it at a very high temperature, though, as overheating can do more bad than good.

2. Sanding

The board’s surface might become uneven after drying, hence the need to level it out. So using sandpaper or good quality sanding sealer, sand the area higher than the rest of the surface so the dried part can be exposed.

Start with a medium-grit and finish with finer grit sandpaper for a smooth finish.

Related read: Difference between sanding sealer and polyurethane.

3. Sealing

Then you can seal with your desired waterproof sealer following the steps described above to prevent a future occurrence.

Can You Fix the Swollen Particleboard?

Yes, you can fix swollen particleboard that has been damaged from water. Although this could result in extensive damage to the board, you want to take great care while repairing it.

How to Fix a Swollen Particleboard

- The first step is to dry the particleboard. When the board has been exposed to a lot of water, you can use a towel to absorb the excess moisture. Then keep the board in a dry area to allow it to dry naturally, but it could take a while, so you could use a hairdryer to reduce the drying time.

- The next thing to do is to buff the swollen area using sandpaper. Not only will it help level the surface of the board, but it will also expose the dried part of the board. Medium-grit sandpaper should also be used to remove the part of the board damaged from swelling before a finer grit one is used. Sanding helps make removing damaged parts easier.

- Proceed to remove the damaged part of the board with a sharp putty knife. You can dig around the area that has become powdery in texture from swelling. Then you want to clean the board well to ensure you have removed all the damaged parts.

- Following removal, filling the holes that have been created is next. A wood filler will come to the rescue here as it would help level the damaged part of the board to other areas around it. If you’re wondering, “Can you put a screw in wood filler?” Go ahead and find out here.

- Then sand again using fine-grit sandpaper for a smoother finish before applying a waterproof sealer.

Quick question: Between olympic waterguard or Thompson’s Water Seal, which one is better? Find out.

FAQs

How do you keep particle board from crumbling?

You can keep particle board from crumbling by keeping it from any area exposed to water, so it does not get into it. This is why it is safer to apply a waterproof sealer like thick pour epoxy resin, solvent-based polyurethane, or a clear acrylic sealer before installation is done to make the board resistant to water.

Can I seal particle board perfectly and make it waterproof?

Even though particle board easily soaks up water, it can easily be sealed and made waterproof. There might be exceptions, but if you apply a double layer of an oil-based polyurethane sealer properly, it will be as water resistant as possible. This is always advised, especially when put into use for outdoor purposes.

Is particle board waterproof?

No, particle board is the exact opposite of waterproof. It is made of porous materials, enabling it to soak up moisture easily. Sealing, however, makes it waterproof. The fact that it acts as a sponge to water is one of the major cons of using a particle board.

What happens to chipboard when it gets wet?

The chipboard becomes swollen and warped after being left wet for a while. This is because it absorbs water easily and takes a while to dry completely. In addition, it also emits an unpleasant smell which might make you want to get rid of it.

Read Also: Can You Stain Manufactured Wood?

Conclusion

In a nutshell, particle board is one of the least resistant to moisture wood products. So to make it durable, stronger, and resistant to extreme weather changes, apply a sealer.

Sealing particle board is easy, as described in the steps above. All you have to do is measure, cut, and apply your desired sealant, preferably solvent-based.

It might take a while to do this, but it is worth every second if you do not want to use your board fearing damage to it. Also, if you already have a damaged particle board, an easy DIY fix is described above to follow.

So what are you waiting for? Purchase that sealer today and get to that construction project!