Wood is a thirsty product. It laps up every liquid that’s spilled, poured, or brushed onto it, except sealer. So when working on porous woods like spruce and cedar, it’s nearly impossible to get a smooth coat without first filling the pores.

Choosing a suitable sealer is critical to achieving a gorgeous, smooth finish. So, what will be your product of choice, sanding sealer vs polyurethane?

If you’ve been working with wood finishes for a while, then you’ve already noticed a problem with the question. So, to prevent any further confusion, we will break down the key differences between them and help you decide when to use each one.

What is a Wood Sealer?

Before we get into this debate, we need to establish what wood sealer is.

Wood sealer is any product applied to raw wood as a protective coating. This protective coat may accomplish a few purposes, including:

- Protecting the wood from water damage

- Decrease the harmful effects of UV rays

- Preserve the beauty of the wood

- Provide a coat before other finishes can be applied

- Extend the lifespan of the wood

Wood sealer can be oil or water-based and could be shellac, stain, lacquer, varnish, or polyurethane, to mention a few.

As you can already tell, some of these wood finishes serve different functions and have distinct properties. While some of these sealers work perfectly fine on their own, some others need help.

That is where sanding sealer comes in.

What is a Sanding Sealer?

When you apply liquid on bare wood, it causes the grain to rise. This raised grain will need to be sanded before getting a smooth finish, so you may need to repeat this process several times. To prevent you from applying too many coats of your finish, you need a sanding sealer.

Sanding sealer is easy to sand, hence the name, and it allows you to apply an even coat on the wood. Sanding sealer is helpful even when you use pore filler.

The most common type of sanding sealer is lacquer with zinc stearate. The zinc stearate is a soft, fluffy soap that makes the lacquer easier to sand.

Another type of sanding sealer is dewaxed shellac. You can make your shellac sealer by dissolving dewaxed shellac flakes in mineral spirits.

What is Polyurethane?

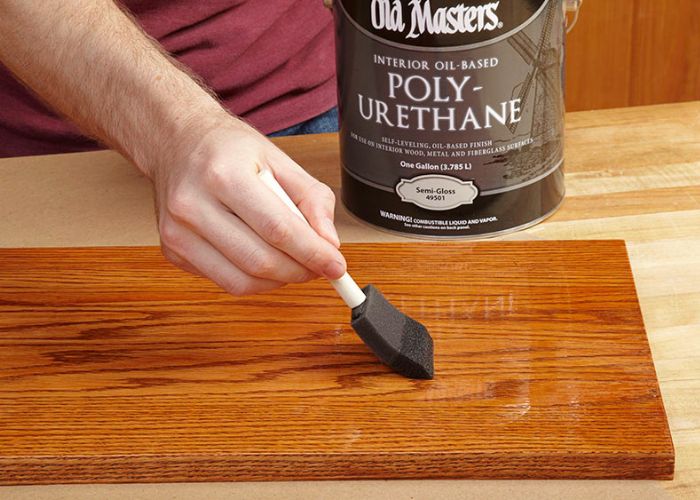

Polyurethane is a durable, water-resistant finish that dries hard. It is used for refinishing furniture but mainly on floors, tables, fences, and other surfaces that need protection from water and scratches. Given how thick polyurethane can be, it is rarely used for high-end furniture.

The two main types of polyurethane wood sealers are:

- Oil-based polyurethane

- Water-based polyurethane

While oil and water-based polyurethane do the same thing, each one has its unique advantages and disadvantages leading to the consideration of water-based polyurethane vs oil-based polyurethane.

For example, oil-based polyurethane gives a warm glow to wood, and it yellows over time. On the other hand, water-based poly dries very clear and remains clear.

Can polyurethane be used outdoors? Let’s find out!

Both types of polyurethane can protect wooden surfaces for over a decade when applied and maintained correctly. Urethane based products, however, are flaking slightly when sanded.

Also, find out what is wipe on polyurethane in our guide.

Sanding Sealer Pros and Cons

- Seals wood grain

- Easy to sand

- Dries in one hour

PROS

- Easy to apply

- Dries quickly

- Reduces the total work time

- Saves on topcoat costs

CONS

- It’s incompatible with all topcoats

- It cannot be used as a final finish

Polyurethane Wood Sealer Pros and Cons

- Protects indoor wood surfaces such as furniture, windows, cabinets, trim and more

- Water based formula dries fast and cleans up with soap and water

- Dries to the touch in 30 minutes with coverage up to 31.25 sq. ft., recoat after 2 hours

PROS

- The thick coat lasts for a long time

- Scratch, chemical and water-resistant

- Dries hard and can handle a lot of wear and tear

- It can be applied in different ways

CONS

- It takes a long time to dry

- Emits high quantities of VOCs

Sanding Sealer Vs Polyurethane Sealer for Wood: In-Depth Feature Comparison

The success of any woodworking project is judged based on the final finish. No matter how good of a job you do with cutting, measuring, joining, carving, etc., it won’t look great without the proper application of a topcoat.

Depending on what you’re working on, you may choose to use sanding sealer and a complimentary finish or use polyurethane.

As sanding sealer and polyurethane don’t exactly do the same job, this comparison will factor in the need to apply a finish on the sanding sealer. Ironically, in some cases, the topcoat might be polyurethane, but more on that after this.

1. Sanding Sealer vs Polyurethane – Level Finish

The primary purpose of sanding sealer is to ensure even application of the wood finish, so this is a fitting place to begin our comparison.

Sanding sealer does a great job of ensuring that finishes like lacquer and dewaxed shellac are level on the surface of the wood. Otherwise, you might find that some parts of the project will feel thinner than others.

It also ensures that you don’t need to sand between coats of lacquer to remove raised grains or make the final film level.

Polyurethane sealant for wood is a film coat that sits on the wood surface instead of being absorbed into it, so you rarely have to worry about unevenness. Plus, most polyurethanes are self-leveling. You need to sand between coats anyway, so the final coat is always level.

In essence, the first coat of polyurethane will do the same work as the sanding sealer, so both products will help you get the smooth finish that makes your work look perfect.

Verdict – tie

2. Wood sealer vs polyurethane – Number of coats

The second significant benefit of using a sanding sealer is to minimize the number of coats you apply. When you use a water-based topcoat directly on wood, even stained wood, it will usually raise the wood fibers.

These hair-like strands will need to be sanded down for you to get a smooth finish. After sanding, you’ll need to apply another coat and keep repeating until you get the desired texture.

When you use a sanding sealer, it will raise the grain of the wood. Typically after sanding the first coat and applying another, the job is done. So, when you apply the topcoat, you won’t need as many layers.

Instead of applying five layers of lacquer, for example, you can apply a single coat of sanding sealer and three coats of lacquer. But, can you put poly over lacquer? Find out in our guide.

On the other hand, water-based polyurethane will raise the grain a few times, so you need to apply several coats. It’s common to apply seven coats of water-based poly on a table before you get the required smoothness.

But before you get carried away, oil-based polyurethane doesn’t have that problem. As long as you have correctly sanded the bare wood, all you’ll need is 2 – 3 coats to get a perfectly smooth finish.

Therefore, using oil-based polyurethane will indeed require fewer coats than when you first use a sanding sealer. However, a sanding sealer will considerably reduce the number of coats you need for every other type of finish.

Verdict – Sanding Sealer

3. Sanding Sealer vs Polyurethane Sealant for Wood – Drying Time

When we talk about the number of coats, we must also consider the length of time it takes for each coat to dry. Lacquer is one of the fastest drying finishes, as it is applied in thin coats. Within an hour, you could be ready to apply another layer.

So, is it worth the stress of first applying a sanding sealer to save a few coats? Depending on the brand, sanding sealer can be just as fast.

Minwax sanding sealer is dry in just 1 hour, after which it is ready for another coat or your first coat of polyurethane.

Both Sherwin Williams and Benjamine Moore sanding sealers need at least 3 hours before you can apply the second coat. That means you could have applied three layers of lacquer or some other quick-drying finish during this time.

The drying times for polyurethane are pretty notorious. Oil-based polyurethanes require up to 12 hours before you can apply the next coat, following a thorough sanding process.

However, water-based polyurethane can be dry in 2 hours, or much less, depending on the brand and method of application. But what do you do when poly doesn’t dry? Find out in our guide.

If you apply polyurethane finishes by wiping or spraying, it dries much faster without compromising durability.

So, unless you are using a particularly fast-drying sanding sealer, the faster approach might be to use water-based polyurethane.

Verdict – polyurethane

4. Sanding Sealer vs Polyurethane – Adhesion

This is one area in which the comparison between these two products gets wonky. When you apply polyurethane on a surface, you keep going until you achieve the desired result. You don’t apply a different product on top of it.

But when you’re using a sanding sealer, you need to use a different finish on it. The problem with sanding sealer is you have to use the right one that goes with the base.

For example, if you’re using a sanding sealer made from lacquer and zinc stearate, you can only apply lacquer over it. The same goes for when you’re using dewaxed shellac.

The reason for that is sanding sealer doesn’t play well with others. Some companies go so far as to tell you to only use their sanding sealer with their products.

This can be annoying if you already bought the sanding sealer or would like to experiment a bit. If you don’t apply the right finish, it won’t adhere to the sealer.

Of course, issues like polyurethane not adhering are not a problem, as you’re essentially layering more of the product onto itself. Ensuring you sand between coats will ensure proper adhesion without any concerns.

Verdict – polyurethane

4. Sanding Sealer vs Polyurethane – Versatility

If you are relying on sanding sealer to make all of your finish applications quicker, you would need to reconsider.

As great as sanding sealer is, it has one glaring limitation: it can only be applied on bare wood. After all, the purpose of sanding sealer is to prevent the finish from seeping into the grain, so it is only fitting that it doesn’t work on other surfaces.

If you try to apply sanding sealer on an existing finish, it simply won’t adhere, plus it’ll be unnecessary. You can, however, apply sanding sealer on stained wood, but this could also be an unnecessary step.

On the other hand, polyurethane can be applied to just about anything. Raw, stained, or even finished surface can be enhanced by polyurethane. You can also apply polyurethane over paint and other surfaces.

Verdict – polyurethane

5. Sanding Sealer vs Polyurethane – Ease of Application

One thing you might find people complain about is how difficult it is to apply polyurethane. When you use a brush, you might get brush streaks. When you use a roller, you might get roller lint.

But even when you do everything right, you still need to wait for hours for each coat before you sand the entire surface and do the dance all over again. That can be frustrating for people who don’t love polyurethane smell in house.

That is why we now have water-based polyurethanes that don’t need sanding between layers. Polyurethanes can also be applied with a brush, pad, roller, wiping cloth, or sprayer.

On the other hand, sanding sealers are typically applied with a synthetic brush. Sanding each coat is easy, thanks to the stearate, as it softens the lacquer.

While that is admirable, the application options for polyurethane are significantly more. Sanding water-based polyurethane is not as easy as a sanding sealer unless when you don’t need to sand it at all.

Cleaning up a water-based polyurethane is also just like that of a sanding sealer. All you’ll need is soap and water. If you used dewaxed shellac to seal wood instead of lacquer sealer, use denatured alcohol or mineral spirits to clean the brush.

Given that polyurethane has all the benefits and then some, this is another clear victory.

Verdict – polyurethane

6. Sanding Sealer vs Polyurethane – Durability

The truest test of a quality product is how long it lasts, which is true for these two contestants.

When using sanding sealer, you fully expect it to hold up the topcoat for as long as possible. Sanding sealer is capable of doing that under one condition – you don’t apply too many coats.

Because the zinc stearate makes the lacquer soft, you don’t want too much of it left when you apply the lacquer finish. Lacquer is a hard finish, but it can be brittle, so it would likely chip or crack if applied on a thick coat of sanding sealer.

That is why you not only have to apply no more than two coats of sanding sealer, but you also need to sand it all out. Of course, not all sanding sealers will fill the pores of the wood grain, but the rest is unnecessary.

If you mistakenly apply three coats, the finish may not be durable.

That isn’t a problem you’ll have with polyurethane. Not only is polyurethane one of the hardest, most durable wood finishes, you also can’t apply too many coats of it. Well, you can, in theory, but applying 2 or 3 more coats won’t make the product less durable.

Verdict – Polyurethane

FAQ

Is sealer the same thing as polyurethane?

No, sealer is not necessarily the same thing as polyurethane. While all polyurethanes are sealers, not all sealers are polyurethane. Sealer is a general term for a wood finish that closes the wood’s pores and protects the surface of the wood. Once you apply a sealer, nothing should penetrate the wood.

When should you use sanding sealer?

You should use sanding sealer on bare wood before applying any finish. You can also apply it to stained wood. The purpose of sanding sealer is to fill the pores and ensure a level surface, so applying it after any finish is redundant. Some manufacturers of wood finishes also suggest you don’t need to apply sanding sealer if you have put stain.

Can I use sanding sealer as a finish?

No, you cannot use sanding sealer as a finish. Wood finish is meant to add an impenetrable layer of protection to the wood and beautify it. Sanding sealer will not protect the wood from water, UV light, scratches, or stains. Therefore, you should always apply a finish on sanding sealer, whether polyurethane, lacquer, or shellac.

Can you put polyurethane over sanding sealer?

Even though polyurethane is itself a sealer, yes, you can apply polyurethane over sanding sealer, as long as it has been recommended by the manufacturer. While the most common sanding sealers are meant for lacquer and shellac, some have been made to go with polyurethane. You cannot apply polyurethane over dewaxed shellac or lacquer mixed with zinc stearate.

Do you need to use sanding sealer?

No, you don’t always have to use a sanding sealer. Sanding sealer is recommended for woods with open grains like cedar, spruce, mahogany, and walnut. You should also use a sanding sealer when working with lacquer. You do not need a sanding sealer for polyurethane, varnish, or spar urethane.

Does polyurethane seal wood?

Yes, polyurethane can be used as a sealer to waterproof the wood’s surface. Using polyurethane helps to create a hard coat that will protect your wood against elements such as harsh UV rays and water damages.

What next? Read our article on how to clean a brush with polyurethane.

Sanding Sealer Vs Polyurethane Final Verdict

The comparison of sanding sealer Vs Polyurethane was unfair from the get-go, but it had to be made to clear up any confusion.

The product you use will depend on what you are working on.

Sanding Sealer Verdict

Use sanding sealer when working on porous woods, bare wood, or applying a finish like shellac or lacquer. (Also, is lacquer better than polyurethane? Find out in our article. )

You may also choose to use sanding sealer when applying poly, but it isn’t necessary.

Polyurethane Verdict

Polyurethane provides unbeatable protection to all wooden surfaces, and it’s extremely durable. You can use polyurethane on any wood, no matter how porous, and still achieve outstanding results.

However, it’s best to use polyurethane alone if you don’t need many coats or don’t need to sand between coats. Otherwise, sanding sealer would save you a lot of coats and time.

Don’t forget to read our benjamin moore regal vs aura comparison guide.

I was very confused on the issue of applying polyurethane over sanding sealers. This cleared it up for me, thank you very much

Thank you for all the great info. Friends had a porch swing made for me for my new little house and I wanted it left as natural wood but have to seal it… Now I know to use water based polyurethane.

Great and clear comparison. Lot of mysteries are cleared out. Thanks and appreciated.

Glad it helped