Several woodworking machines have been developed over the years to help woodworkers process wood faster and more productively. In addition, woodworking machines increase wood processing precision.

Unfortunately, the sheer number of woodworking machines can make it difficult to identify the right tools for your next project. The confusion is worse when buying your workshop’s first set of machines.

So, today, we want to discuss the most important machines in the modern workshop to help you plan better.

Types of Woodworking Machines

- Electric saws

- Drill presses

- Nail guns

- Electric drills

- Sanders

- Planers

- Wood routers

- Mortisers

- Grinders

- Wood lathes

- Wood shapers

- Tenoning machines

- Combination machines

What’s a Woodworking Machine?

A woodworking machine is a piece of electric-powered equipment used to process wood in workshops, timber mills, and furniture factories. The machines perform various tasks, from woodcutting to shaping and carving.

Electric motors typically power woodworking machines. A built-in electric motor rotates the blade or drill bit, allowing the machine to cut, bore, or shape wood. Onboard controls enable the user to manipulate the machine.

Categories of Woodworking Machines

Woodworking machines are broadly categorized as handheld power tools or stationary machines. Handheld power tools are portable, lightweight equipment you can hold in one hand throughout the project. These include electric drills and nail guns.

On the other hand, stationary machines are large, heavy equipment permanently stationed strategically for easy access. The table saw is a good example.

You can also categorize woodworking machines as either manual or computer operated. Manual machines involve significant human intervention. For instance, though it’s electric powered, you must manually load boards into and maneuver the electric drill to cut accurately.

Computer-controlled machines don’t require much human intervention to load and process wood. You only need to feed the onboard computer with the necessary data. Then the machine loads wood and processes them as instructed without further human effort.

Even better, some computer-controlled woodworking machines are pre-programmed or arrive with templates for your convenience. So, you pick a template from the control panel, and the machine will process the wood as per that template as you watch.

Note that woodworking electric tools and machines are considered safe for use on wood since wood does not conduct electricity.

Pros and Cons of Woodworking Machines

Woodworking machines are a valuable investment for many reasons but also come with a few drawbacks that you must keep in mind. Consider the following pros and cons before you purchase one;

Woodworking Machinery Pros

- Highly efficient

- Exceptional accuracy

- Fast and time-saving

- Extremely versatile

- Excellent for intricate designs

- High resale value

Woodworking Machinery Cons

- High upfront costs

- High operating costs (power bills)

- They are costly to repair

- Potential for costly errors/accidents

Do you want to venture into woodworking? Here’s the question you should ask, Do woodworkers make good money?

Types of Woodworking Machines to Consider for your Workshop

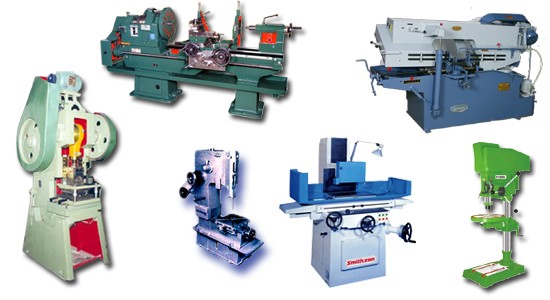

Let’s now look at the different types of woodworking machines. Which are the most common machines, and what do they do?

Electric saws

Electric saws are some of the most important tools in the woodworker’s workshop. They are used to precision-cut straight or angled wood pieces at different thicknesses. You can also use saws to cut holes in wood.

Electric saws can be portable or floor-standing. Common portable electric saws include chain, jig, circular, and reciprocating saws otherwise known as a Sawzall.

On the other hand, popular floor-standing electric saws include automated bandsaws, panel saws, radial arm saws, table saws, and scroll saws

Nail guns

The nail gun is arguably the next most important power tool in the modern workshop after saws. Also known as nailers, nail guns allow you to drive nails into wood pieces without a hammer. Instead, you just load the nailer, make contact with the wood surface, and pull the trigger.

There are different types of nail guns targeting specific applications. For instance, framing nail guns are for connecting large dimensional lumber pieces. Meanwhile, brad nail guns are for tiny nails used in trims.

Finish nailers, siding nailers, roofing nail guns, pin nailers, and hardwood flooring nail guns are other common categories.

Read more: Best nailer for baseboards.

Electric drills

An electric drill (or power drill) is a pistol-shaped handheld power tool primarily used to bore holes in different materials (not just wood). It also works as a screwdriver. Indeed, there’s no need for a screwdriver if you have a reliable electric drill.

Besides boring holes and screws, you can use an electric drill to drive hex-head bolts. Also, you can use it as a sander, grinder, or paint mixer with the proper head attachment.

Common power drills include hammer drills, rotary hammers, impact drivers, core drills, and ground augers. Drills are either corded or cordless.

Drill press

We would have bundled the drill press together with other electric drills. However, it’s better to list it separately as it has a much wider scope of applications.

So, what is it? A drill press is a stationery or benchtop power tool for cutting holes in wood, metal, plastic, and other materials. There are two main types – stationery and benchtop models.

The drill press uses various types of bits in different diameters to bore perfect holes. However, unlike a standard power drill, drill presses facilitate side-to-side tilting. Some even have LEDs to guide you.

Related Post: How to Screw Nail Into Wood Without Drill

Sanders

A woodworking sanding machine is a powerful tool that automatically smooths wood surfaces, so you don’t have to do it with your hands.

Sanders work differently depending on the type of sander. For instance, disc sanders (the most common) use an abrasive disc or grinding wheel. Meanwhile, drum and sleeve sanders drive expanding drums that accept abrasive sleeves.

Other types of wood sanders include the orbital sander, planetary sander, and belt sander. A handheld sander is best for small applications. However, full-time woodworkers should consider a bench-installed or floor-mounted sander.

Planer

A planer is a woodworking tool used to shave down wood surfaces to make them smoother and more even.

There are two main categories of planers – surface and thickness planers. A thickness planer (called a thicknesser in British English) is used to plane wood pieces into an even thickness. Meanwhile, surface planers are used to make surfaces smooth and even.

You can also invest in a jointer. What are jointers used for? Jointers are special planers used to make the edges of wood boards smooth and flat for precision joining. Alternatively, a few machines combine all three functions.

Wood routers

The router is one of the most versatile tools in woodworking. It consists of a flat plane with a rotating shaft or bit that sticks out from the bottom. An electric motor drives the shaft, which rotates a circular blade.

You can use the wood router for many jobs, including curing dadoes, rabbets, and dovetailing. Routers are also applicable in making cutouts, sharp edges, joints, and decorative surface cuts.

Routers come in two main styles – one with a fixed base and another with a plunge base. Fortunately, a few modern “combo kits” allow you to switch between the two styles.

If you’re interested in alternative methods on how to round wood edges without router, consider reading about alternative techniques to achieve this specific woodworking task.

Recommended read: What size router bits for door hinges?

Mortiser

A mortiser is a woodworking machine that cuts square and rectangular holes in timber. It gets its name from its main purpose – cutting mortises for mortise and tenon joints.

Unlike other tools on this list, mortises are generally electric-powered. To use it, you first secure the workpiece to the work surface, then lower the mortiser into the identified location.

Smaller mortises (known as chisel mortises) use a spinning bit and chisel, while larger mortises (aka chain mortises) use a cutting chain.

Angle grinders

An angle grinder is a handheld device for cutting, polishing, planing, carving, and deburring wood into the desired shape. It attaches to various tools, including discs, cutters, pads, and wheels.

Angle grinders are available in three main types; electric powered, pneumatic, and gas powered, depending on the primary power source.

Most importantly, angle grinders are highly versatile. You can use it in other sectors such as masonry (to cut stones and ceramic tile) and metalwork (to cut, polish, and clean surfaces).

Want to learn how to attach 45 degree angle wood? check out our article for step-by-step instructions and useful tips.

Wood lathe

A wood lathe is a versatile cutting tool designed for wood shaping and creating wood lathe projects that sell. It attaches to various tools, such as a spindle roughing gauge, skew chisel, and scrapers, and rotates to cut and shape the predefined surfaces.

It’s easy to use too. You only need to secure the wood piece to the lathe, attach the cutting tool, and power the lathe. Then, the rotating lathe will shape the wood as you wish.

There are several types of lathes. However, the center, bench, vertical, turret, and automatic wood lathes are the most common.

With all this in mind, remember to check out our top recommendations when searching for the best budget lathe.

Wood shaper

A wood shaper (also known as a shaper in North America or spindle molder in Europe) is a stationary woodworking machine used to mill profiles on wood stock.

Wood stock/blanks are fed into the molder, and the vertical or horizontal spindle raises or lowers the cutter head, which rotates at 3,000 to 10,000 rpm. This allows you to cut and shape wood into various profiles.

Wood shapers are often compared to routers. The main difference is that shapers are much larger and more powerful. Additionally, they can cut more profiles.

Related Post: Best Wood Lathe for Bowl Turning

Tenoning machine

A tenoning machine is a powerful tool used to produce tenons that fit into mortises to make tenon and mortise joints.

The main advantage of the tenoning machine is it produces multiple tenons in batches. Moreover, you can use it for every possible tenon style, from round to square and clipped tenons.

There are two broad categories of tenoning machines – single-ended tononers and double-ended tenoners. Both types feature multiple motors and cutter heads of different diameters, lengths, and horsepower.

Combination machines

Finally, a combination machine combines the function of several machines to save costs and space.

For instance, a combination machine may function as a table saw and a planer. You just need to reconfigure it. Similarly, others combine the functions of a shaper, jointer, and table saw.

The main downside of combination machines is they take time to reconfigure from one tool to another. They are also expensive.

Related Post: How to Screw Two Pieces of Wood Together Lengthwise

How to Care for Woodworking Machinery

- Use your machines for the right purpose

- Clean the machine regularly

- Ensure the power cords aren’t broken

- Store the machine in a cool, dry place to prevent rust

- Sharpen blunt blades promptly

- Replace broken blades accordingly

Related Post: Best Leather Woodworking Apron

FAQs

What’s the most versatile woodworking machine?

The table saw is the most versatile woodworking machine. It is undeniably the most important stationary machine in the woodworker’s workshop – the heart of the standard workshop that allows you to perform miter cuts, cross cuts, rip cuts, and many other types of cuts.

What’s the most popular woodworking tool?

Common carpentry tools, such as saws, are crucial in woodworking because every project starts by sizing the wood. With over two dozen varieties, ranging from handheld gent saws for crafting intricate joints to powerful table saws that can swiftly cut through large sheets of wood, their importance cannot be overstated.

What’s the best all-in-one woodworking machine?

Many woodworking experts consider the HX 310 Pro the best combination machine. The 5-in-1 machine combines the functions of a durable panel saw, spindle molder, jointer, planer, and mortising machine. With this set, you only need saws and drills to complete your workshop.

What type of machine is used to ensure a smooth wooden surface?

Planers are the machines mainly used for wood smoothing. They feature sharp blades that shave wood surfaces to smoother, more even surfaces while reducing the thickness to the desired size. Planers are available in two basic categories; small handheld models and floor-mounted industrial planers.

Summary

Woodworking machines, powered by electric motors, are invaluable in the modern workshop as they increase efficiency, accuracy, and productivity. Some of the most important woodworking machines to consider when starting are saws (especially the table saw), power drills, and routers.